Kleenoil Bypass Filter System

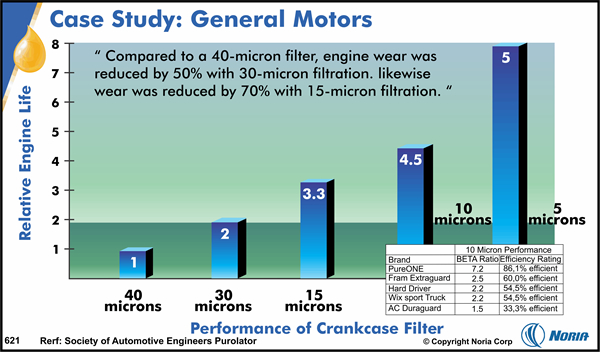

The Kleenoil Bypass System is a bypass oil filtration system that passes only a small portion of the total oil flow through a very dense filter cartridge at about 2 to 3 quarts per minute. At this speed, it is possible to remove particles down to 1 micron (3 absolute) and 99.95% of all water. Besides eliminating particle contamination and water, Kleenoil bypass filters extend engine oil life up to 5 times and hydraulics oil up to 10 times, reduce engine wear and component wear, dramatically reducing downtime. Kleenoil products are applicable to engines, transmissions and hydraulic systems.